Work

Unity3D

3D Printing

Prusa i3

Type

Installation

Year

2018

For a Gatorade project we needed to track products in realtime on a Capacitive Touch table.

Users should be able to place down a range fo 10 different products on a screen and compare their ingredients.

So I started to prototype and think about ways to simulate human touches. As we needed conductive materials for that I researched a bit and found a Proto-Pasta material with exact these characteristics.

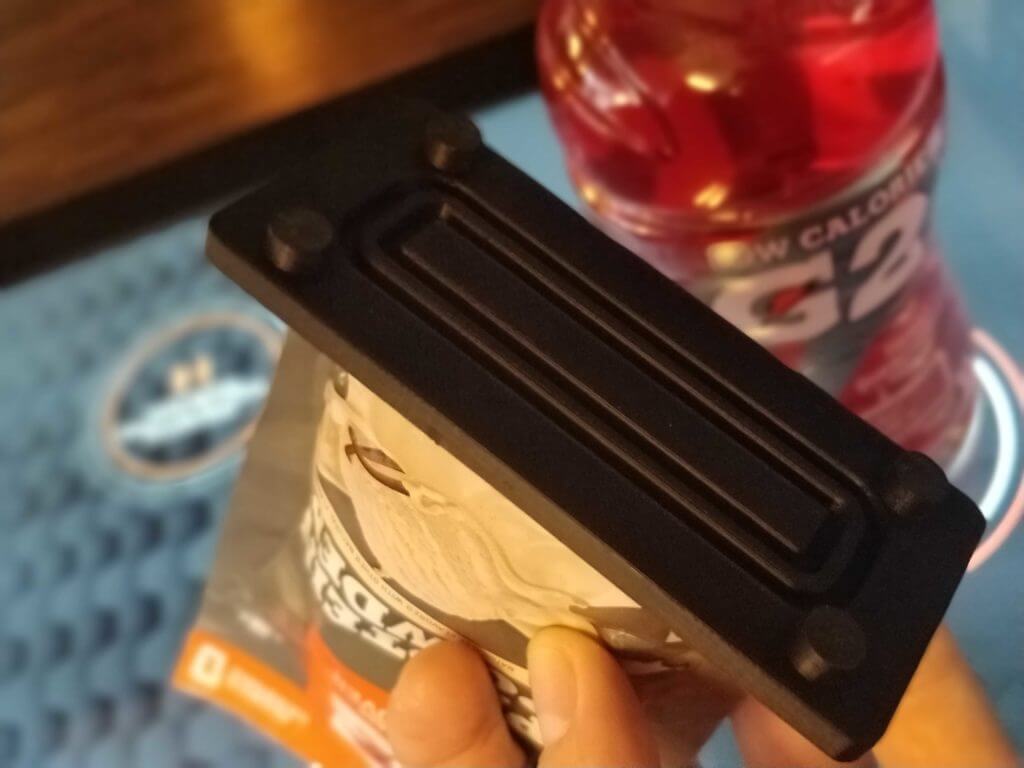

I printed out baseplates, with 3-4 feet, each with an individual pattern.

3D Print of one of the baseplates:

Attached to a product, I was able to differentiate the patterns and load the individual product information into our application, hosted in a Craft CMS.

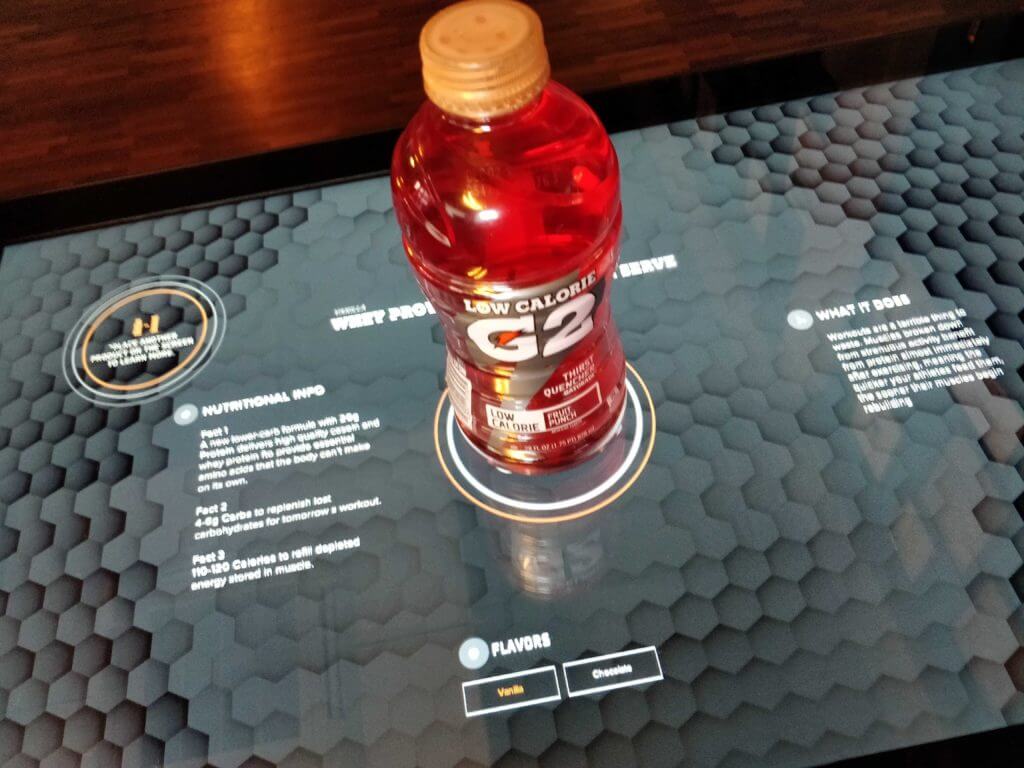

Baseplate with 4 touch points:

Users could move the products around and information tiles were animated and placed near the physical objects.

The object detection was developed as a Unity3D Prefabb, based on a mathematical probability calculation to track products, even if touchpoints were lost during movements for a certain amount of frames/second. An admin panel could be used to add new patterns to our database by placing them on the screen and save them individually to our Product-DB.

G2 product on the screen.

We focused on the approach of tracking object on the screen with the help of simulated touch events, rather than using tracking cameras or wide range RFID technology. The goal was to simplify the installation and to avoid ceiling-mounts, which are most of the time hard to calibrate and to keep them in a fixed and stable position on popup-stores and tradeshows.

The touchtables were part of our installations for Gatorade in 2017. Read more about the whole setup in another blogpost.